EnviroGear®, a product brand of PSG®, a Dover company, is a global provider of innovative, high-quality industrial gear pumps for the safe and efficient transfer of high-value and hard-to-seal fluids. EnviroGear’s mission is to engineer the world’s safest and most reliable internal gear pumps by understanding customers’ needs and providing unparalleled customer service through a highly skilled and experienced team.

Industry Leading Customer Service and Factory Support

5-Year Limited Warranty

EnviroGear warrants that the pumps, accessories and parts we manufacture or supply are free from defects in material and workmanship.

15-Day Factory Lead Time for Pumps

Our pumps are delivered quickly, in 15 days or less, while maintaining our signature quality and reliability.

5-Day Factory Lead Time for Part

When you need a replacement part, you need it quick. Our unmatched 5-Day Lead Time for parts ensures your pump is fixed quickly.

Competitive Prices

We offer unique, cost-effective solutions that fit your specific needs while helping maintain your bottom line.

ATEX, CE, FDA, and TR CU Compliant

EnviroGear has met the criteria for various industry certifications, including ATEX, CE, FDA and TR CU compliances.

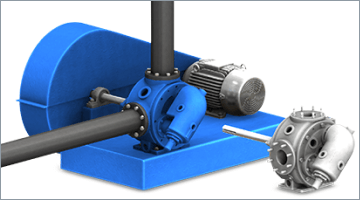

EnviroGear® has three different pump series to meet your specific needs, and for whatever the job may be.

E Series

Your Seal-Less, Leak-Free Solution

G Series

Your Alternative to Viking® Internal Gear Pumps

V Series

Kicking Viking® in the Asphalt

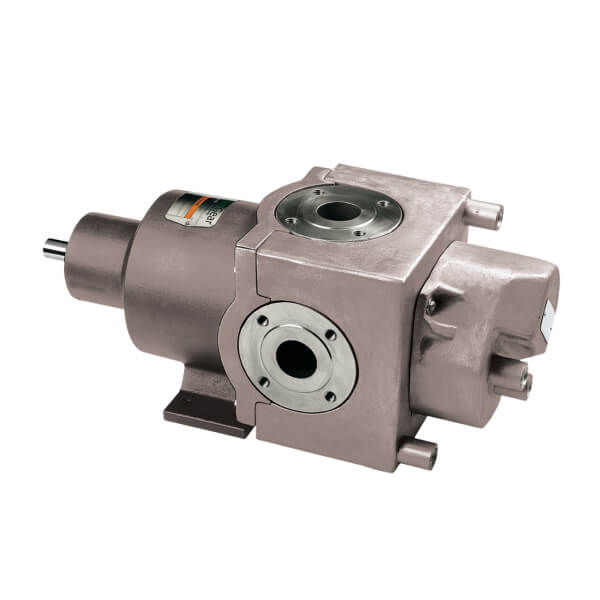

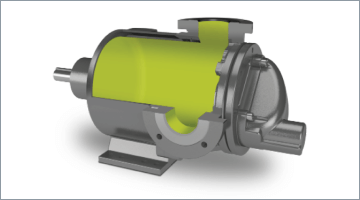

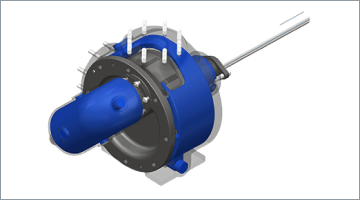

EnviroGear® E Series Pump

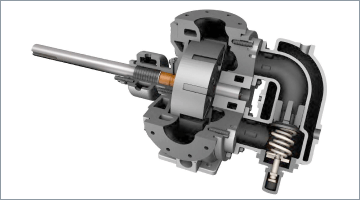

Your Seal-Less, Leak-Free Solution

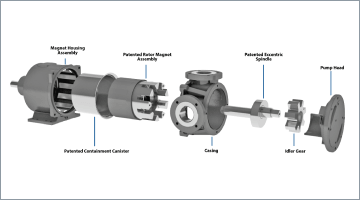

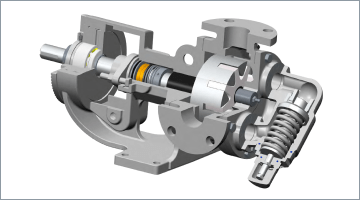

Take your pump performance to the next level with EnviroGear® E Series Magnetically Coupled Seal-less Internal Gear Pumps. Innovative, durable and environmentally-friendly, E Series pumps have been engineered to be a cut above the competition thanks to a revolutionary design with a patented between-the-bearing support system. This one-of-a-kind design eliminates leaks and reduces mechanical wear, helping increase the safety of site personnel and the environment. In addition, no other mag drive internal gear pump offers a lower upfront cost, lower total cost of ownership or more reliability than the E Series.

E Series Pump Interactive View

AVAILABLE MATERIALS

- Ductile Iron

- Carbon Steel

- Stainless Steel

MAX TEMPERATURE

- 500°F (260°C)

CAPACITY

- 15 gpm to 500 gpm (3.4 m³/h to 113.6 m³/h)

MAX PRESSURE

- Ductile Iron – 200 psi (13.8 bar)

- Carbon Steel – 200 psi (13.8 bar)

- Stainless Steel – 150 psi (10.3 bar)

Features

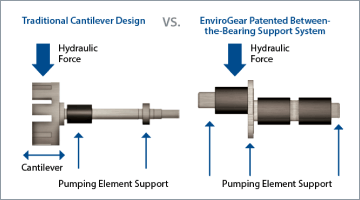

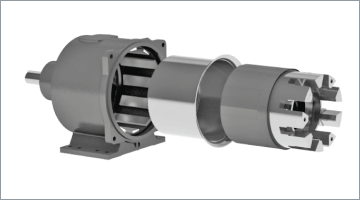

Between-the-Bearing Support System

Eliminates the damaging effects of cantilevered loads that are present in competitor internal gear pumps, maximizing rotor, idler and bushing life.

One Fluid Chamber Design

Greatly improves fluid circulation through the magnetic coupling, resulting in lower operating temperatures, longer magnet life, and more effective cleaning and flushing processes.

High-Torque and Compact Magnetic Coupling

High-strength magnetic couplings are standard to allow for more operational flexibility, with inner magnets mounted directly to the rotor for an extremely compact design.

Simple Design

The need for only seven primary components improves reliability and reduces system complexity while easing maintenance and repair.

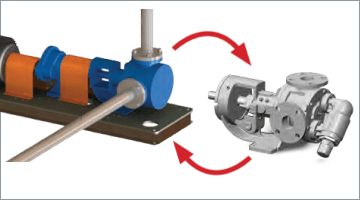

Competitor Pump Interchangeability

Interchangeable with up to 95% of the packed, mechanically sealed and seal-less internal gear pumps in use today, with no need for piping, driver, baseplate or coupling modifications.

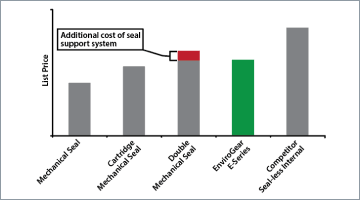

Affordable Upfront Solution

Due to the simple, seven primary-component part design, E Series pumps have a much lower investment cost than competitors’ mag drive pumps.

E Series Brochure

E Series IOM

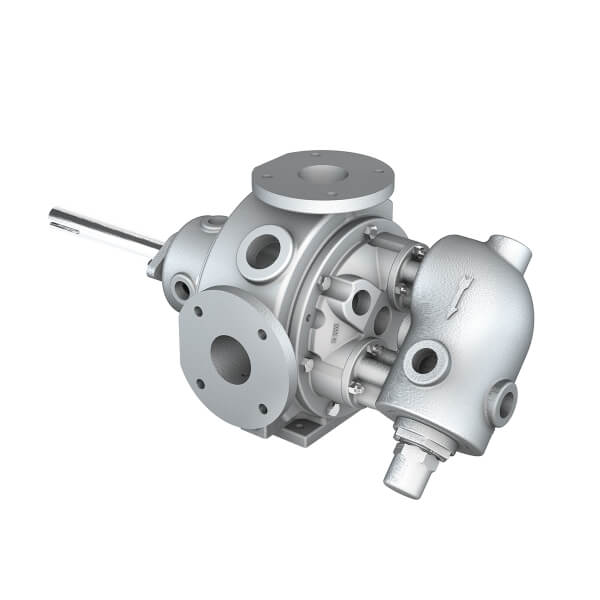

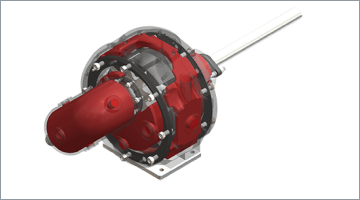

EnviroGear® G Series Pump

Your Alternative to Viking® Internal Gear Pumps

When you expect more from your current gear pump, EnviroGear® G Series Internal Gear Pumps have you covered. As the high-quality, reliable alternatives to competitive models, G Series positive displacement gear pumps have the durability, flexibility and efficiency you need to safely and securely handle all your challenging fluid-handling applications. When it’s time for an upgrade, replace your current pump worries with a durable, flexible and efficient solution that provides peace-of-mind performance backed by superior and experienced customer service and factory support.

AVAILABLE MATERIALS

- Cast Iron

- Carbon Steel

- Stainless Steel

MAX TEMPERATURE

- 650°F (343°C)

CAPACITY

- 15 gpm to 500 gpm (3.4 m³/h to 113.6 m³/h)

MAX PRESSURE

- Cast Iron – 200 psi (13.8 bar)

- Carbon Steel – 200 psi (13.8 bar)

- Stainless Steel – 150 psi (10.3 bar)

Features

Competitor Pump Interchangeability

Interchangeable with up to 95% of the mechanically sealed, packed and seal-less internal gear pumps in use today, with no need for piping, driver, baseplate or coupling modi cations. G Series pumps are designed to be part-for-part replacements for many competitor pump models and are available in cast iron, carbon steel and stainless steel.

Direct Replacement Part Interchangeability

G Series parts are designed to be direct replacements for Viking® H, HL, K, KK, L, LQ, LL, LS, Q and QS models. Available in cast iron, carbon steel and stainless steel construction. See our Cross Reference Guide.

Seal Chamber with Universal Design and Heavy-Duty Oversized Bearing Housing

An oversized bracket and seal chamber allows the use of numerous sealing technologies, including packing, mechanical seals and lip seals. The large cast-iron bearing housing allows the mechanical seals to be removed without the need to take the pump out of service.

G Series Brochure

G Series IOM

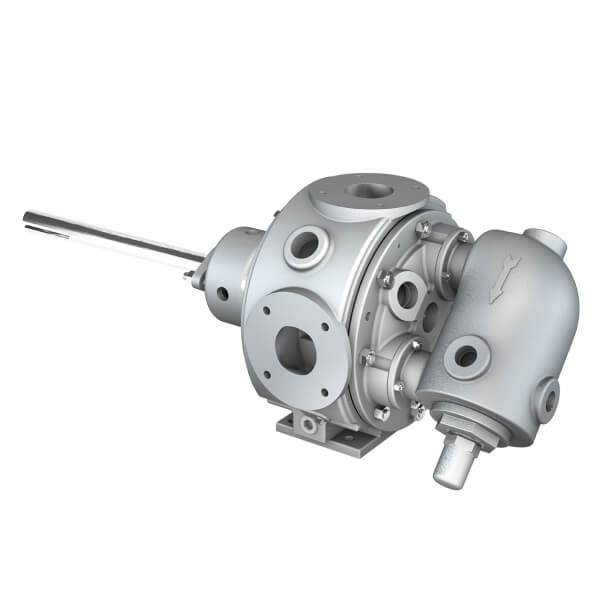

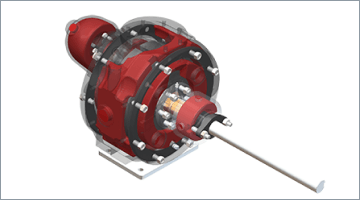

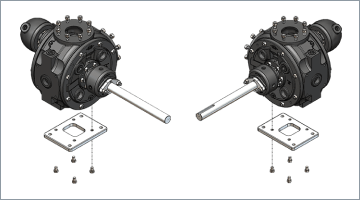

EnviroGear® V Series Pump

Kicking Viking® in the Asphalt

Introducing the EnviroGear® V Series Asphalt Pump. We understand that pumping asphalt is a challenge as it changes temperatures and can range from a solid to a liquid with a wide variety of fluid characteristics depending on the chemical makeup. And – let’s face it – the competition isn’t getting the job done. EnviroGear V Series pumps address and overcome these challenges, and do so in a way that is safe, reliable and economical.

AVAILABLE MATERIALS

- Cast Iron

MAX TEMPERATURE

- 450°F (232°C)

CAPACITY

- 90 gpm to 450 gpm (20 m³/h to 102 m³/h)

MAX PRESSURE

- 100 psi (6.9 bar)

Features

The V Series’ innovative design includes a wide variety of new and standard-setting features that have established a series of industry firsts within the asphalt market.

Industry’s Largest Jacketed Surface Area

The V Series Pumps feature up to 35% more jacket surface area than the competition, which improves system reliability by incorporating the following features:

- The unique ability to utilize the jacketed head and pressure relief valve (PRV) simultaneously

- Jacketing located behind the pump rotor, which removes a known cold spot that can result in hard startups and premature pump and seal failures

- The industry’s largest jacketed surface area on the pump case and PRV that enables uniform heating whether using steam or hot oil

The V Series’ innovative design includes a wide variety of new and standard-setting features that have established a series of industry firsts within the asphalt market.

Industry’s Largest Jacketed Surface Area

The V Series Pumps feature up to 35% more jacket surface area than the competition, which improves system reliability by incorporating the following features:

- The unique ability to utilize the jacketed head and pressure relief valve (PRV) simultaneously

- Jacketing located behind the pump rotor, which removes a known cold spot that can result in hard startups and premature pump and seal failures

- The industry’s largest jacketed surface area on the pump case and PRV that enables uniform heating whether using steam or hot oil

V Series Internal Gear Asphalt Pump

Image above represents typical jacket surface area of competitor pumps

V Series Jacketed Surface Area

Image above represents typical jacket surface area of competitor pumps

V Series Jacketed Surface Area

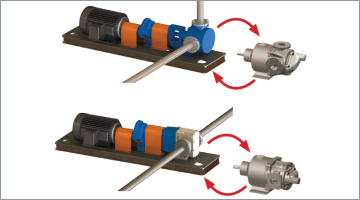

First Direct Replacement for Viking® 34 Series Pump & Parts

First drop-in replacement for the Viking® 34 Series Pump. Replacing an existing Viking pump usually requires no modification to the piping, driver, baseplate or coupling, while also keeping flow rates unchanged. V Series components are also part-for-part interchangeable with the Viking 34 Series Pump and offer very specific design enhancements to improve reliability. See our Cross Reference Guide.

Rotatable Flanges

Allows the operator to use both right-handed and left-handed flange orientations as needed without additional lead times or costs associated with left-hand configuration pumps.

High-Strength Ductile Iron Gear Material as Standard

High-strength ductile iron is EnviroGear’s standard offering with other hardened material component options available to provide improved pump life:

- Surface hardened case, head, rotor, idler and shaft

- Special high-temperature hardened steel idler pin

- Hardened cast iron idler bushing, RBS radial bushing, and stationary thrust washer

- The unique ability to utilize the jacketed head and pressure relief valve (PRV) simultaneously

- Jacketing located behind the pump rotor, which removes a known cold spot that can result in hard startups and premature pump and seal failures

- The industry’s largest jacketed surface area on the pump case and PRV that enables uniform heating whether using steam or hot oil