Blackmer Pumps

Blackmer sliding vane pumps are used in a wide variety of industrial applications. Self priming and with excellent suction capabilities, Blackmer pumps are used for liquid transfer from trucks, rail cars, tank farms, drums & chemical tote transfer. Blackmer vane pumps are designed to pump lubricants, solvents, coatings, paints, jet fuel, edible oils, glycol, thinners and all types of chemicals. OEC Fluid Handling can provide Blackmer pumps in cast iron, ductile iron and 316 stainless steel construction and discharge sizes from 1” to 12” – flows from 10 to 2,220 GPM.

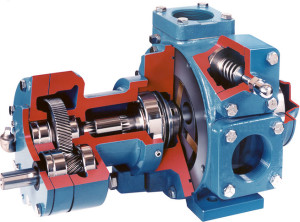

GX Model

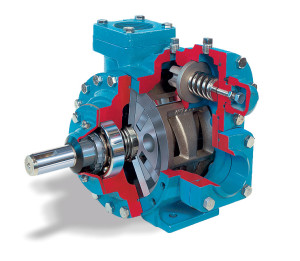

X Model

NP Model

ML Model

STX Model

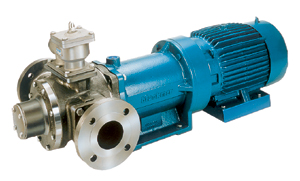

SNP Model

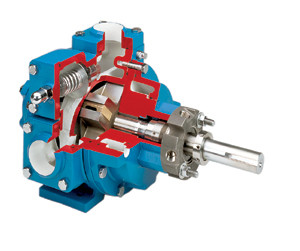

SMVP Model

HXL Model

https://www.youtube.com/watch?v=wJyKcmbjmNs

The GX models feature an integral head mounted gear reduction drive that is self-aligning. The GX pumps are the first choice for economy and compactness. The X type pumps can be used with a wide variety of gear reducers and drive arrangements.

Standard NP and MLN pump models are constructed with self-lubricating internal sleeve bearings and Teflon® impregnated shaft packing. Sealing options include single or multiple commercial mechanical seals, lip seals or triple lip seals. Jacketed heads are available for both models.

The GX, X, and NP pump models (two through four-inch port sizes) are offered with standard NPT tapped or optional weld, ANSI or DIN companion pipe flanges. The MLN4 model has ANSI compatible flanges.

Blackmer SNP and SMVP pump models are typically used in handling a wide variety of corrosive or caustic fluids, and liquid foods such as sugars, syrups and flavor extracts. Both series have 316 stainless steel construction and self-lubricating carbon sleeve bearings which allow dry running for priming and line stripping. All models are fitted with Teflon seal rings, replaceable end discs and non-metallic vanes that eliminate galling and provide extended pump life.

The SNP models are available with Teflon- impregnated shaft packing, lip seals, triple lip seals, lantern rings or commercial mechanical seals. An optional two-way relief valve is available on all models through 2-1/2 inch port size. ANSI compatible flanges are standard on sizes through 2-1/2 inches. The SNP3 has an internal relief valve and weld companion flanges. For control of fugitive emissions, the SMVP seal-less series is offered with samarium cobalt magnetic couplings that assure zero shaft leakage. Blackmer SMVP pumps provide the Best Available Control Technology for handling expensive, hazardous or toxic fluids.

Clean, non-corrosive industrial liquids and petroleum products. Typical applications include fuel oils, lube oils, jet fuels, gasoline, edible oils, and a variety of solvents and thinners such as esters, ketones, naphtha’s, ethers, amines, aromatics, alcohol’s, turpentine’s, glycols and many other similar liquids. Blackmer SNP pumps are typically used in handling a variety of corrosive or caustic fluids such as acids, brines and liquid foods such as sugars, syrups, beer, beet juice, cider and flavor extracts. Designed for high volume transfer of non-corrosive liquids ranging in viscosity from thin solvents to heavy oils and molasses. HXL pumps are especially suited for barge, ship and terminal operations where their self-priming and high suction lift capabilities enable them to strip tanks and barges clean. Loading and unloading corrosive and non-corrosive fluids: sulfonic acids, specialty chemicals, solvents, latex paints, liquid sugars, and vegetable oils.

-

-

- Chemical Process

- Food and Beverage

- Power Generation

- Pulp and Paper

- Pharmaceuticals

- Refining

- Industrial Waste Water Treatment

-

-

-

- Mining and Minerals

- Plastics and Rubber

- Biofuels

- Cosmetics and Personal Care

- Plating

- Detergent and Cleaning Mfg.

- Textiles

-

GX Model

Blackmer GX & X series pumps have long been popular for transferring a wide range of non-corrosive, non-abrasive industrial liquids and petroleum products. The GX and X models are fitted with Blackmer mechanical seals and external grease lubricated ball bearings. The GX pumps have built in gear reducers that make a compact installation. GX pumps are available 2”, 2 ½” 3” and 4” ports. Flow ranges from 30 to 510 GPM.

Blackmer GX Series Installation Operation Manual and

GX2B Parts List

GX2.5B Parts List

GX3E Parts List

GX4B Parts List

X Model

Blackmer X pumps are available in 1”, 1 ½”, 2”, 2.5”, 3” & 4” ports. Flow ranges from 10 to 224 GPM. OEC Fluid Handling has supplied GX & X pumps to bulk oil, chemical and solvent manufactures for over thirty-five years. Pre-piped pumping systems from OEC Fluid Handling and Blackmer provide long lasting service in the most rugged production environments.

Blackmer X Series Installation Operation Manual

X2B Parts List

X2.5B Parts List

X3E Parts List

X4B Parts List

NP Model

Blackmer NP cast iron pumps features product lube internal sleeve bearings, standard teflon® impregnated shaft packing and full flow relief valve. Sealing options for Blackmer NP pumps include single or multiple commercial mechanical seals, lip seals or triple lip seals. Jacketed heads are available of all sizes of NP pumps. 1 ½”, 2”, 3” and 4” NP pumps are available from OEC Fluid Handling.

Blackmer NP Series Installation Operation Manual

NP1.5B Parts List

NP2F Parts List

NP2.5F Parts List

NP3F Parts List

NP4F Parts List

NPH4F Parts List

ML Model

Blackmer MLX pumps are external bearing pumps constructed of ductile iron. Available only in 4”, MLX pumps provide an excellent pump for unloading trucks, rail cars and tanks. The full flow relief valve provides maximum protection of the pump and can be used as an external relief. OEC Fluid Handling can provide MLX pumps as pre-piped skids with pumps, meters, controls and valves.

Blackmer ML Series Installation Operation Manual for MLX4B, MLXW4B, MRLX4B, MRLXW4B, MLN4B, MRLN4B

Parts List for MLX4B, MLXW4B, MRLX4B, MRLXW4B

Parts List for MLN4B, MRLN4B

STX Model

Blackmer STX pumps are designed for loading and unloading corrosive and non-corrosive fluids: DEF, sulfonic acids, speciality chemicals, solvents, latex paints, liquid sugars, and vegetable oils. STX pumps are constructed of 316 stainless steel with external ball bearing construction. Blackmer’s chemical mechanical seals and non-metallic vanes assure long life for the transfer of corrosive liquids.

Blackmer STX Series Installation Operation Manual

STX3 Parts List

STX3-DEF Parts List

STX1220A Parts List

STX1220A-DEF Parts List

STX2A Parts List

STX2A-DEF Parts List

SNP Model

The complete line of Blackmer SNP & SMVP series of 316 stainless steel pumps is available from OEC Fluid Handling. SNP pumps are heavy duty and are used by the chemical process, pharmaceutical, food, paints and coatings industry to pump a wide variety of corrosive or caustic fluids, liquid foods such as sugars, syrups and flavor extracts. SNP pumps provide flow ranging from 15 to 265 GPM depending on product viscosity.

Blackmer SNP Series Installation Operation Manual

SNP1.25 Parts List

SNP1.5 Parts List

SNP2 Parts List

SNP2.5 Parts List

SNP3A Parts List

SMVP Model

Blackmer SMVP 316 stainless steel sliding vane pumps combine proven sliding vane technology with a seal-less magnetic coupling. The result is a completely leak-free operation that minimizes product waste and improves production yield. Ideal for the safe transfer of critical high value fluids. OEC Fluid Handling can supply Blackmer SMVP pumps in 1 ½”, 2”, 3” and 4” sizes with ANSI or DIN flange connections.

Blackmer SMVP Series Installation Operation Manual for SMVP15C and SMVP30C

SMVP15C Parts List

SMVP30C Parts List

Blackmer SMVP Series Installation Operation Manual for SMVP50C, SMVP100C, SMVP200C

SMVP50C Parts List

SMVP100C Parts List

SMVP200C Parts List

HXL Model

Blackmer HXL pumps are designed for large flow rates. HXL pumps can provide flows from 750 to 2,220 GPM in size 6”, 8” and 10” discharges. Casing manufactured in ductile iron, Blackmer HXL pumps are built for long and rugged service for pipeline, terminal, barge unloading and critical loading services. OEC Fluid Handling has supplied Blackmer HXL pumps to all major oil and pipeline companies.

Blackmer HXL Series Installation Operation Manual

HXL6G Parts List

HXL8G Parts List

HXLJ8G Parts List

HXL10E Parts List

OEC Fluid Handling pump assemblies and pre-piped skids are available designed to perform to your process requirement. Replacement Blackmer NP, SNP and SMVP pumps and parts are available from OEC Fluid Handling. Our stock of pumps and parts are available from our Spartanburg, S.C. warehouse for quick delivery.